In the world of automotive engineering, turbochargers have emerged as a revolutionary technology that significantly enhances vehicle performance. By harnessing the power of exhaust gases, these devices are designed to boost engine output and improve fuel efficiency. Understanding how turbochargers operate and their benefits can offer insights into why many modern vehicles are equipped with this innovative feature.

Turbochargers work by forcing more air into the engine’s combustion chamber, allowing for a more efficient and powerful combustion process. This increased air supply leads to higher horsepower without requiring a larger engine displacement. As a result, drivers experience a remarkable boost in performance, often accompanied by lower fuel consumption compared to naturally aspirated engines.

Moreover, the advantages of turbocharging extend beyond mere power gains. With tighter emission standards and a growing emphasis on sustainability, turbochargers play a critical role in achieving greater fuel economy. By enabling smaller, lighter engines to produce the same power as their larger counterparts, turbocharging allows manufacturers to create vehicles that are both powerful and more environmentally friendly.

Understanding Turbocharger Mechanics and Functionality

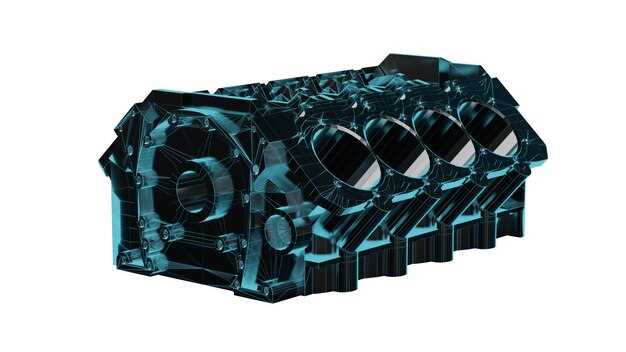

A turbocharger is a key component designed to enhance an engine’s performance by increasing its efficiency and power output. It operates on the principle of forced induction, where it compresses the air entering the engine. This compression allows more air, and consequently more fuel, to be introduced into the combustion chamber. The result is a significant boost in horsepower without the need for a larger engine.

The turbocharger consists of two main parts: the turbine and the compressor. The turbine is connected to the exhaust system and uses the engine’s exhaust gases to spin a shaft connected to the compressor. As exhaust gases flow through the turbine, they generate rotational energy, which is transferred to the compressor, located on the intake side. This brief sequence of energy transfer is critical to the turbocharger’s functionality and efficiency.

The compressor draws in ambient air, compresses it, and pushes it into the engine’s intake manifold. The compressed air is at a higher pressure and temperature, allowing for more oxygen molecules in the combustion process. By enhancing the amount of air provided to the engine, a turbocharger helps to achieve a more complete combustion, leading to improved fuel economy and reduced emissions.

Another critical aspect is the turbocharger’s capability to maintain consistent boost pressure across various engine speeds. This characteristic helps eliminate turbo lag, a common issue where there is a delay in response when accelerating. Modern turbochargers often incorporate advanced technologies such as variable geometry to actively optimize boost levels, ensuring immediate responsiveness and efficient operation regardless of the driving conditions.

In summary, understanding the mechanics of a turbocharger reveals how it effectively enhances performance. By compressing air, it enables a more efficient combustion process that translates into increased horsepower and fuel economy, making it an essential component in modern automotive engineering.

How Boost Pressure Affects Engine Performance

Boost pressure is a critical factor in determining the performance of an engine equipped with a turbocharger. When the turbocharger compresses the intake air, it increases the amount of air and fuel that can be introduced into the combustion chamber. This process results in a higher air density, allowing for a more efficient combustion and ultimately enhancing engine output.

As boost pressure increases, more oxygen is available for the combustion process, which empowers the engine to generate additional horsepower without significantly increasing engine size. This is especially advantageous in smaller engines, where turbocharging can effectively simulate the performance of a larger engine while maintaining or improving fuel economy.

However, it is important to note that excessive boost pressure can lead to detrimental effects. High boost levels may cause knocking or pinging, as the air-fuel mixture ignites prematurely. Engine components must be designed to withstand increased stress and heat, necessitating improved materials and enhanced cooling systems

To optimize performance, manufacturers often incorporate a boost controller to regulate pressure levels. This device monitors engine parameters and adjusts the turbocharger’s output, ensuring a balance between power and reliability. By managing boost pressure carefully, turbocharged engines can achieve improved fuel efficiency without sacrificing performance.

In summary, boost pressure plays a crucial role in maximizing engine performance through turbocharging. By carefully balancing the pressure, engines can benefit from increased horsepower and better fuel economy, making boost management a vital consideration for any turbocharged setup.

Benefits of Turbocharging for Fuel Economy

Turbocharging offers significant advantages for improving fuel economy by optimizing engine performance. By utilizing exhaust gases to drive a turbine, turbochargers effectively increase the amount of air entering the engine. This boost in air supply allows for more efficient combustion, leading to better fuel utilization.

One of the primary benefits of turbocharging is the ability to maintain engine power while using smaller displacement engines. This downsizing results in lower fuel consumption without sacrificing performance. For example, a turbocharged 2.0L engine can produce the same power as a naturally aspirated 3.0L engine, thereby improving overall efficiency.

Additionally, turbochargers help reduce engine load during acceleration. By providing an immediate boost of power, drivers can achieve desired speeds more quickly, which can lead to less fuel being consumed compared to traditional engines that might require prolonged pedal acceleration.

| Benefit | Description |

|---|---|

| Improved Efficiency | Enhanced air-fuel mixture allows for more complete combustion, reducing waste. |

| Downsizing Potential | Smaller engines with turbochargers can replace larger, less efficient ones. |

| Quick Power Response | Instantaneous power delivery reduces the acceleration time, improving fuel usage. |

| Emissions Reduction | More efficient combustion leads to fewer emissions and a smaller environmental footprint. |

In conclusion, turbocharging serves as a vital technology for improving fuel economy by allowing for efficient power generation with reduced fuel consumption. The resulting benefits include improved efficiency, downsizing potential, quick power response, and lower emissions, making turbocharged engines a favorable choice for today’s environmentally conscious drivers.

Choosing the Right Turbocharger for Your Engine

Selecting the appropriate turbocharger for your engine is crucial to achieving optimal boost, performance, and efficiency. Understanding the various factors that influence your choice can significantly impact your vehicle’s output and driving experience.

Here are key considerations to keep in mind when choosing a turbocharger:

- Engine Size: The displacement of your engine plays a critical role in determining the best turbocharger. Smaller engines may benefit from a smaller turbo that provides quick spool-up, while larger engines can handle larger turbos that produce more power at higher RPMs.

- Power Goals: Define your performance objectives clearly. If you aim for a modest increase in horsepower and better fuel economy, a smaller turbo may suffice. For significant horsepower gains, consider larger turbos capable of delivering higher boost levels.

- Boost Level: Specify the desired boost pressure for your setup. Higher boost correlates with increased power, but it also requires supporting modifications to your engine, such as upgraded fuel injectors and intercooler systems.

- Tunable Options: Some turbochargers offer adjustable wastegates and other tunable features. Selecting a turbo with these options allows you to fine-tune boost levels for specific driving conditions and preferences.

- Turbo Lag: Consider the trade-off between power and lag. Turbochargers that provide substantial boost typically take longer to spool up, resulting in turbo lag. Choose a design that balances responsiveness and power delivery to match your driving style.

- Application: Different applications may necessitate different turbo designs. For track racing, quick responsiveness might be prioritized, while street applications may focus on a balance of power and drivability.

- Durability: Ensure the turbocharger is built with quality materials that can withstand high temperatures and pressures. Opt for reputable brands with good warranties and reviews from other users.

- Supporting Mods: Assess whether additional engine modifications are required to handle the increased boost from your chosen turbocharger. This might include upgrades to the exhaust system, intake, or engine internals.

In summary, choosing the right turbocharger is a significant decision that will directly affect your engine’s performance and efficiency. By carefully considering these factors and matching the turbocharger to your specific needs, you can achieve the desired boost and improve not only horsepower but also fuel economy.

Common Myths About Turbochargers Debunked

Turbochargers are often surrounded by misconceptions that can lead to misunderstandings about their functionality and benefits. Here are some common myths debunked:

Myth 1: Turbochargers are only for high-performance vehicles. Many believe that turbochargers are exclusive to sports cars or racing machines. In reality, they are increasingly found in everyday vehicles. Turbocharging allows manufacturers to produce smaller, more efficient engines that can deliver equivalent or better performance than larger naturally aspirated engines, boosting both horsepower and fuel economy.

Myth 2: Turbochargers create too much lag. While some older turbo models experienced lag before the boost kicked in, modern designs have made significant strides in reducing this delay. Advanced technologies, such as twin-scroll turbochargers and variable geometry turbos, help deliver power more responsively, ensuring a smoother driving experience without noticeable lag.

Myth 3: Turbocharged engines require more maintenance. Another prevalent belief is that turbocharged engines have higher maintenance needs. In fact, routine maintenance for both turbo and non-turbo engines is largely the same. Regular oil changes and checking for any potential leaks or issues are sufficient to keep a turbocharged engine running smoothly. The key is to use high-quality oil and ensure proper care.

Myth 4: Bigger turbos mean better performance. While it might seem intuitive that a larger turbo would provide more boost, this isn’t always the case. A turbo’s efficiency and size must match the engine’s design and intended use. An oversized turbo can lead to excessive lag, negatively impacting performance. Proper tuning and integration are crucial for maximizing benefits.

Myth 5: Turbochargers overheat easily. While turbochargers generate heat due to their operation, modern engineering has addressed this concern. Adequate cooling systems and materials designed to withstand high temperatures greatly reduce the risk of overheating. Proper installation and the use of high-quality components further enhance their reliability.

Understanding these myths helps consumers appreciate the advantages of turbocharging, particularly regarding performance enhancement and fuel efficiency. By embracing turbo technology, drivers can enjoy a more dynamic driving experience while also benefiting the planet through improved fuel consumption.

Maintenance Tips for Maximizing Turbocharger Efficiency

To ensure your turbocharger operates at peak performance, regular maintenance is essential. First, always use high-quality engine oil specifically designed for turbocharged systems. This oil should have the right viscosity to maintain adequate lubrication and prevent overheating.

Next, routinely check and replace the air filter. A clean air filter ensures that the turbocharger receives an optimal supply of air, which is crucial for efficient operation. Clogged filters can restrict airflow, leading to a decrease in performance and possible damage to the turbocharger.

Inspect the intercooler and associated piping for leaks or damage. A malfunctioning intercooler can negatively affect the intake air temperature, reducing the efficiency of the turbocharger. Ensure that all connections are secure and that there are no signs of wear and tear.

Monitor the boost pressure regularly. If the boost pressure is outside the manufacturer’s specifications, it may indicate a malfunction in the turbocharger or related systems. Addressing these issues promptly can help prevent more significant problems down the line.

Additionally, allow your engine to warm up before driving aggressively, especially if your vehicle has a turbocharger. This practice lets the oil circulate effectively, ensuring the turbocharger is properly lubricated, which is vital for its longevity.

Consider having your turbocharger inspected by a professional during routine servicing. Technicians can identify potential issues before they become critical, helping maintain performance and overall engine health.

Lastly, be cautious with modifications. While performance upgrades are tempting, they can strain the turbocharger and lead to efficiency loss. Always consult a professional before making significant changes to your vehicle’s setup.